daramu house foyer

DARAMU HOUSE, BARANGAROO | Lend lease + tzannes

Together with its sister building, Daramu House marks the threshold between Sydney CBD and Barangaroo South. Design by Tzannes, the pair of buildings are constructed entirely from engineered timber and showcase new capabilities in mass timber fabrication and construction.

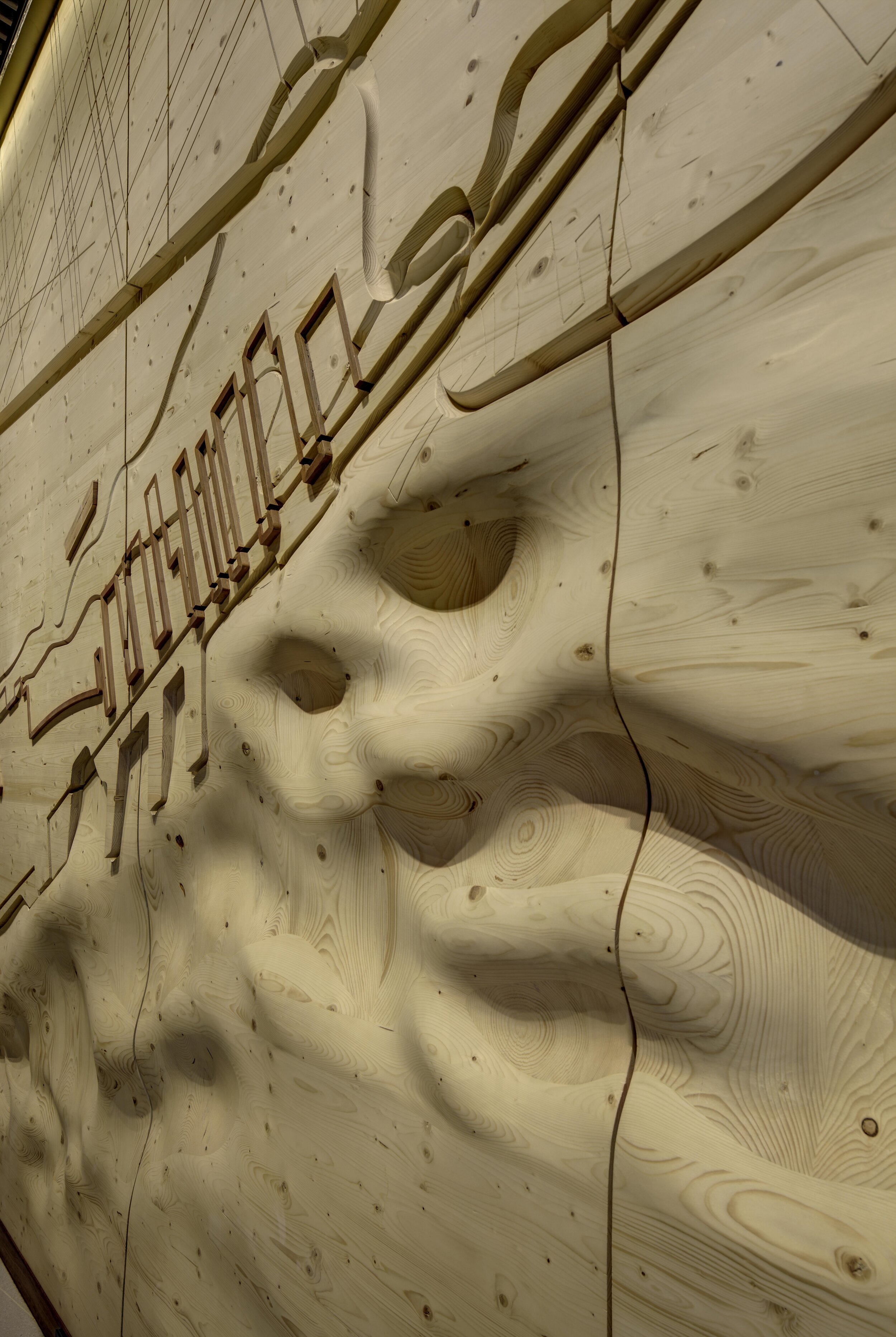

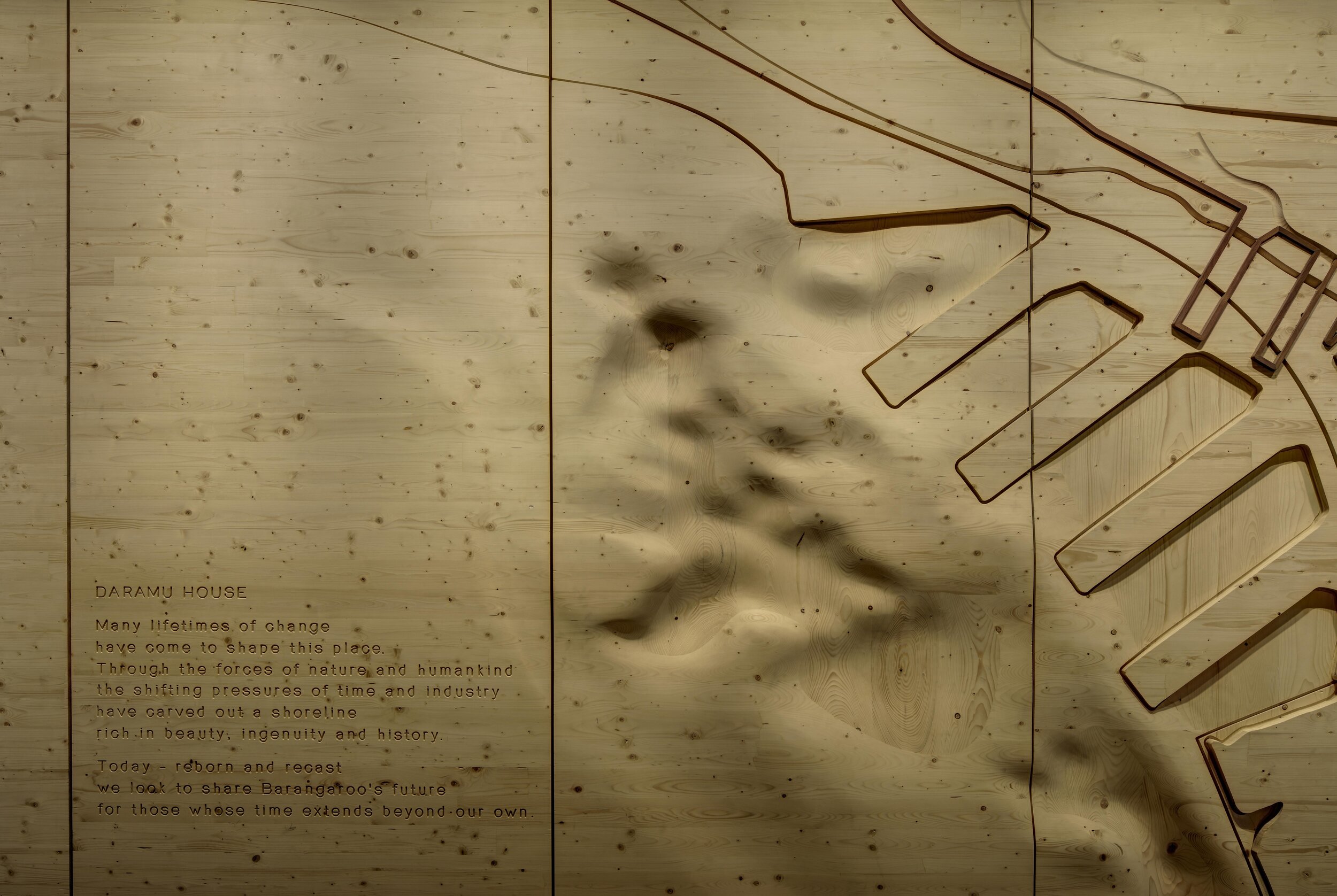

Structural timber elements continue down to the ground level foyer of Daramu House to create a distinctive and warm entry to the precinct and building. As visitors move through the foyer, an interpretive design unfurls along the spruce panels of the northern wall. Blending innovation, history and culture, the design is an interpretation of Barangaroo’s changing foreshores which are carved along the length of the timber by advanced milling machinery. Each is an echo of the mark industrial innovation has left on the precinct. It reects the enduring and formative inuence of the harbour on the industrial vibrance on Barangroo and Sydney more broadly.

The vision for this project was to deliver a distinctive entry to the building and precinct. However, its conception was driven by a team initiative to push the limits of timber fabrication and further its capacity for excellence through design and innovation. The project has illustrated the potential for this technology to achieve outcomes beyond its demonstrated capability to date.

For this work Anna Charalambous and Nicole Larkin were recognised by the National Association for Women in Construction as the recipient of the Innovation Award 2020. It acknowledges a group of women within a team demonstrating their substantial contribution to the implementation of innovative work practices in New South Wales, to areas such as construction, design, policies, learning and development.

The project was also recognised by Good Design Australia, receiving the 2020 Good Design Award for Architectural Interiors.

Image Credits: Brett Boardman, Lend Lease, Ben Guthrie, Tony Lam, Kevin Mak

Initially conceived to push the capabilities of timber fabrication, this project also delivered a unique and remarkable civic artwork. To achieve this, the team adapted a process designed for large scale structural timber elements to operate at a much ner scale, carving sculpted surfaces and geometries into timber panels. This involved adapting the software which operated the machinery, cutting tools and engineered timber panels which were cut into. It altered the way the design was documented and the design itself was informed by these new capabilities. This was essential to enable the surface of the timber to be carved into owing, undulating surfaces.

It required the machinery to make a signicant leap from operating in 2 dimensions to functioning in a highly complex, multidirectional manner, sculpting the timber into organic forms without visible joins or breaks. This innovation opens up signficant possibilities for the design of mass timber buildings.

The benefits of mass timber construction rely on eciencies gained in the prefabrication of elements, designed and manufactured to be rapidly assembled onsite. The natural warmth and visual appeal of engineered timber also lends itself to remaining exposed and negating the need for additional internal cladding.

Building the capacity to design and shape these components without leaving the production line achieves much greater breadth in the aesthetics of the timber components. It encourages teams to expose and celebrate the engineered timber materiality of the structure and has the potential to create a distinct aesthetic for mass timber buildings.

Project Team

Lead Industrial Designer, Anna Charalambous | Lead Designer, Nicole Larkin

Project Director, Jonathan Evans | Project Director, Jeremy Thompson

Client, Daniel Doyle | Project Architect, Tony Lam

Technician, Andreas Gemmrich